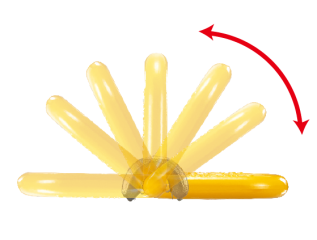

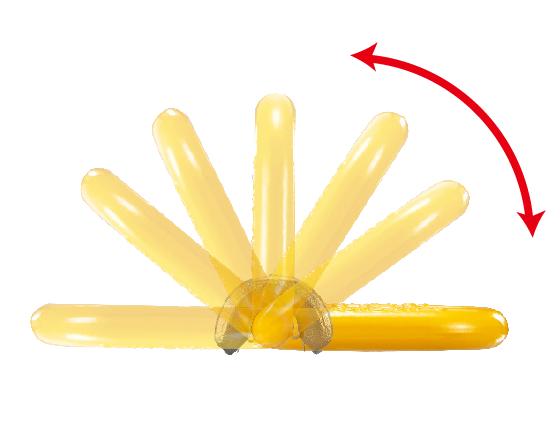

• Pivots through 180°.

• Manufactured from forged alloy steel, quenched and tempered.

• Manufactured and tested in accordance with EN 1677-1.

• Load rated parts are 100% magnaflux crack detected.

• Individual forged parts are traceable to Test Certification.

• Proof tested to 2.5 times the WLL.

• All YOKE Lifting points meet or exceed all the requirements of ASME B30.26.

• WLL forged onto each product for quick and easy identification.

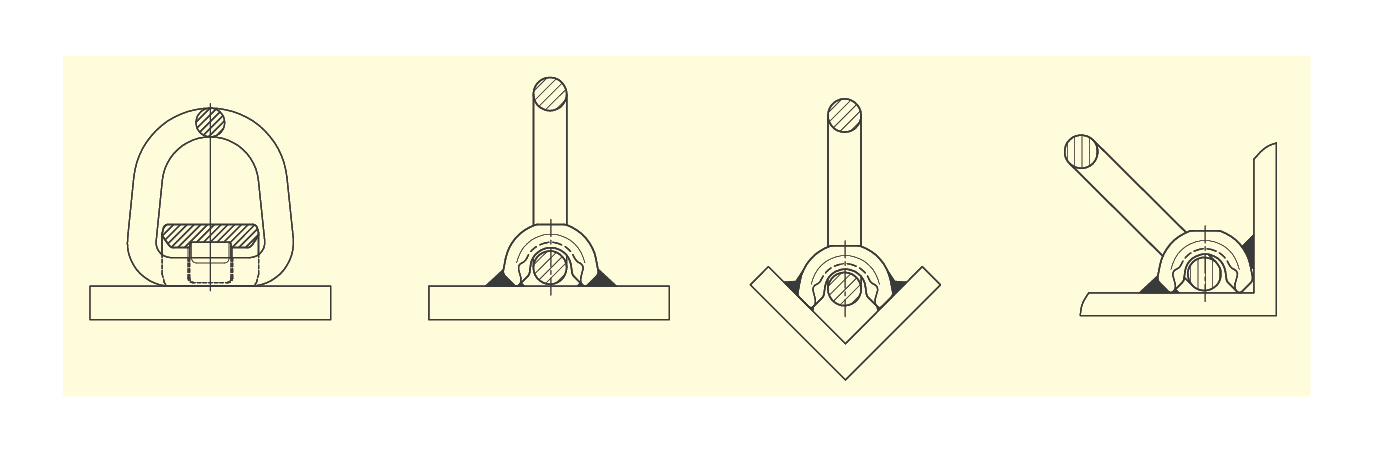

• Lugs designed to assist the welding process.

• A protected spring keeps the load ring in a required position. The parts are connected in such a way that they remain captive. The spring also reduces noise caused by vibrations.

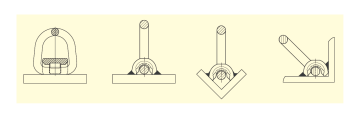

• Never apply load except in the same direction with the pivot direction.

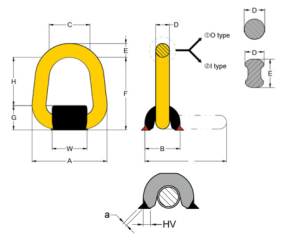

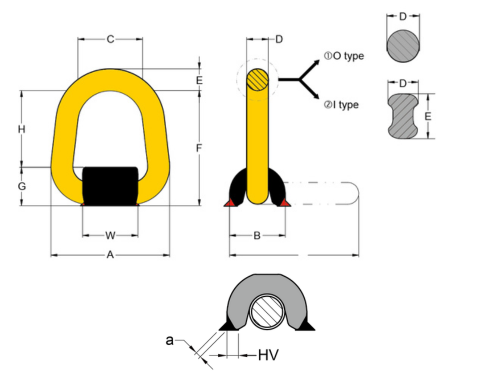

8-057-1T/8-057-3T/8-057-5T →O type

8-057-1T/8-057-3T/8-057-5T →O type

8-057-10T→I type

| Item NO. | file download | Compare | Working Load Limit | Dimensions | N.W. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tonnes | A | a | C | D | E | F | G | H | HV | L | W | kg | |||

| 8-057-10T | Download | Compare | 10 | 146 | 4 | 82 | 20 | 30 | 141 | 53 | 88 | 10 | 191 | 75 | 2.8 |

| 8-057-5T | Download | Compare | 5 | 120 | 3 | 66 | 22 | 22 | 118 | 41 | 77 | 7 | 157 | 64 | 1.3 |

| 8-057-3T | Download | Compare | 3 | 98 | 3 | 58 | 17 | 17 | 85 | 31 | 54 | 6 | 114 | 58 | 0.9 |

| 8-057-1T | Download | Compare | 1 | 83 | 3 | 48 | 14 | 14 | 86 | 27 | 58 | 5 | 109 | 50 | 0.5 |

| 8-057-8T | Download | Compare | 8 | 121 | 4 | 68 | 26 | 26 | 122 | 53 | 69 | 10 | 169 | 60 | 2.6 |

| Item NO. | file download | Compare | Working Load Limit | Dimensions | N.W. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tonnes | A | a | C | D | E | F | G | H | HV | L | W | lbs | |||

| 8-057-10T | Download | Compare | 22000 | 5.75 | 0.16 | 3.23 | 0.79 | 1.18 | 5.55 | 2.09 | 3.46 | 2.95 | 7.52 | 2.95 | 6.2 |

| 8-057-8T | Download | Compare | 17600 | 4.76 | 0.16 | 2.68 | 1.02 | 1.02 | 4.8 | 2.09 | 2.72 | 2.36 | 6.65 | 2.36 | 5.7 |

| 8-057-3T | Download | Compare | 6600 | 3.86 | 0.12 | 2.28 | 0.67 | 0.67 | 3.35 | 1.22 | 2.13 | 2.28 | 4.49 | 2.28 | 2 |

| 8-057-1T | Download | Compare | 2200 | 3.27 | 0.12 | 1.89 | 0.55 | 0.55 | 3.39 | 1.06 | 2.28 | 1.97 | 4.29 | 1.97 | 1.1 |

| 8-057-5T | Download | Compare | 11000 | 4.72 | 0.12 | 2.6 | 0.87 | 0.87 | 4.65 | 1.61 | 3.03 | 2.52 | 6.18 | 2.52 | 2.9 |

__25J02wgzG6.jpg)

__25J02wgzG6.jpg)